The Working Principle of a Color Sorter for Recycled Metals

The core principle of a color sorter is to identify and separate materials based on their optical properties (such as color, brightness, and texture) through a high-speed, automated process. It functions like a highly sophisticated "eye" and "hand" working in perfect synchrony.

The process can be broken down into four key stages:

1. Feeding & Alignment

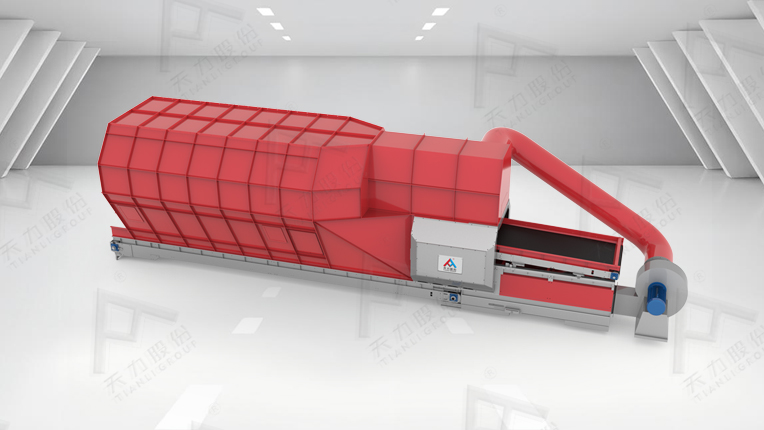

Mixed recycled metal scraps (e.g., a mix of copper, aluminum, zinc, or contaminated materials) are fed into the machine via a vibrating feeder or conveyor. This system evenly distributes the materials and guides them into a single layer, ensuring they fall freely and in a orderly manner through a chute.

2. Detection & Identification

As the particles fall, they pass through a dedicated Detection Zone.

Optical System: Here, a high-resolution, high-speed line-scan camera or CCD camera captures images of each particle.

Illumination System: A specialized, consistent LED light source (often multiple wavelengths) illuminates the particles to eliminate shadows and enhance color contrast. This is crucial for distinguishing between metals with similar hues (e.g., different copper alloys or anodized aluminum).

3. Data Processing & Decision Making

The captured image data is instantly sent to a Central Processing System (a powerful industrial computer with specialized algorithms).

The software analyzes the color, brightness, and shape of each particle in real-time.

It compares these characteristics against pre-set criteria (the "recipe" for the desired material, e.g., "select all bright copper particles" or "reject dark, oxidized aluminum").

Upon finding a match for rejection, the system calculates the exact position and timing for the ejection command. Advanced models now use AI and deep learning to improve accuracy over time with complex materials.

4. Precision Ejection

The identified target particle (the impurity or the metal to be separated) reaches the Ejection Zone.

Based on the command from the processing system, an array of high-speed, precision solenoid valves or nozzles is activated.

These nozzles release a short, powerful burst of compressed air, precisely knocking the target particle out of the main product stream.

The result is two (or more) separated streams: the Accepted Product and the Rejected Material.