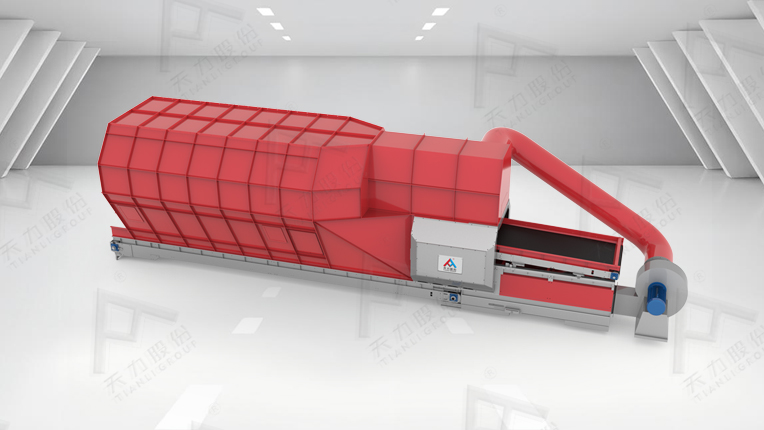

Eccentric eddy current separator adopts the integrated design concept, the vibration feeder, magnetic roller, drum magnet, conveyor belt, eddy current separator integrated in one, can reduce the total volume of equipment. The drum magnet in front end of the machine, help to remove the ferrous metal to prevent it go to eddy current separator; At the back end of the equipment, through the principle of eddy current, the non-ferrous metal impurities such as copper and aluminum in the material are ejected out through the force, finally achieving the effect of separating non-ferrous metal and other materials.

【Scope of Application】:

It is mainly used to separate copper, aluminum and other non-ferrous metals from industrial waste and domestic waste. Life waste incineration produced slag, life waste, paper mill tailings, waste glass recycling, wood chips, waste metal recycling, electronic waste recycling, waste plastic recycling.

【Product Advantage】:

● Employ imported bearing with long life and good performance.

● Adopt PLC programmable control with one button start and simple operation

● The magnetic roller adopts effective device protection to prevent the magnetic system from falling off when running at high speed.

● Adopt intelligent touch control system, frequency conversion control, more stable and reliable operation

● The machine adopts special technology, precision build, equipment running noise and vibration is very small

● A variety of inspection and alarm systems are installed to monitor the operation of each critical component in real time

Customer site: