Tianli Equipment Technology

China. PET Flakes Recycling Plant

- CRAFT:PET分选行业解决方案

- PRECISION:分选精度可达90%以上

- OUTPUT:处理量3T/h

- SITE:浙江

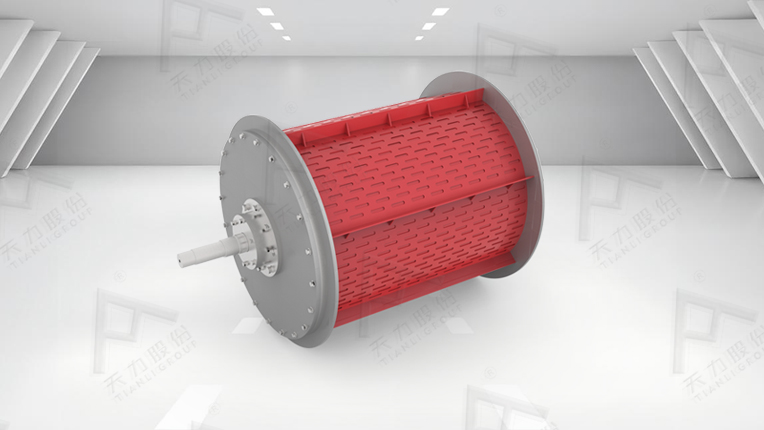

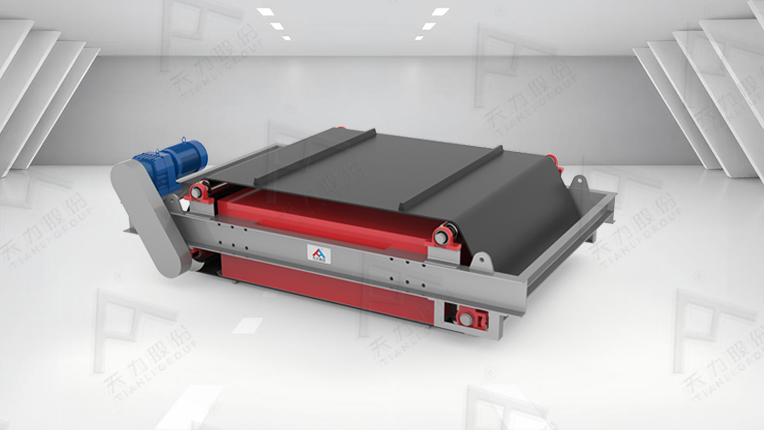

The project practised by a new environmental protection enterprise specializing in PET flakes recycler. The annual production of PET flakes is more than 100,000 tons, which is widely used in polyester filament, staple fiber, special fiber and other fields. Because the metal in the flakes, such as iron and aluminum, has a great impact on the later granulation or wire drawing process, and also affects the purity of the finished product, for this kind of situation, the eddy current separator equipment of our company has effectively solved many problems in the production process.

In 2017, the company added 3 units of eddy current separator on the basis of the original production line, with a single processing capacity of about 1.5 tons. Two years later, two sets of eddy current separation equipment with larger processing capacity were added to the Phase 2 project. Combined with the efficiency of overband magnet and eddy current separator, the product quality and competitiveness of the company were greatly improved.